Dongguan Tonyin Hardware Products Co., Ltd

Tel:189-0260-0506

Add:Building 8, No. 73 Lianfeng Sanheng Road, Dalingshan Town, Dongguan City, Guangdong Province

After the completion of processing and production, the surface treatment of the barbecue net is usually required to make the product beautiful, rust proof, and corrosion-resistant. Generally speaking, there are two methods for surface treatment of barbecue nets: electrogalvanizing and polishing. Below, we will introduce these two processes.

Electrogalvanizing, also known as cold plating, is the application of electroplating methods to galvanize the surface of barbecue nets. The process mainly involves immersing the barbecue nets and zinc blocks in the electrolyte, passing through the positive and negative DC currents respectively, and averaging the waste coating. The surface of the barbecue nets galvanized in acidic electrolytes is brighter, while the surface of the barbecue nets galvanized in alkaline electrolytes is whiter, but the two qualities are not different.

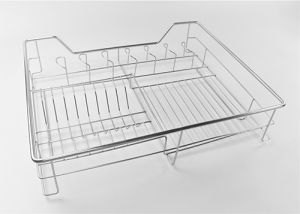

This process is primarily applied to the surface treatment of low-carbon steel wire (iron wire) barbecue nets. 2. Regarding stainless steel barbecue net products, the commonly used surface treatment method is polishing, which includes mechanical polishing, chemical polishing, and electrochemical polishing. Each of these three methods has its own advantages and disadvantages.

Mechanical polishing has high brightness. Its disadvantages are high labor intensity, severe pollution, and its gloss cannot be different. The gloss persists for a short time, causing stuffiness and rusting. Silk screen deep processing products are more suitable for processing simple parts, medium and small products. The advantages of chemical polishing, a deep processing product for wire mesh, are low investment in processing equipment, fast polishing speed, high efficiency, and good corrosion resistance.

Its disadvantage is poor brightness, gas overflow, ventilation equipment required, and difficult heating. This type of wire mesh deep processing product is suitable for processing small batches of complex parts and products with low brightness requirements for small parts. Electrochemical polishing, a deeply processed product of wire mesh, has the advantages of long-lasting mirror gloss, stable process, low pollution, low cost, and good corrosion resistance. Its disadvantages are high pollution prevention, large one-time investment in processing equipment, complex parts requiring tooling and auxiliary electricity, and many consumers also require cooling equipment. Suitable for mass consumption, this type of silk screen deep processing product is mainly used in products, export products, and public service products. Its processing technology is stable and the operation is simple.